For decades, The Merrick Group has been a heat exchanger cleaning company. We provide heat exchanger cleaning services for various industrial clients. The Merrick Group can perform your heat exchanger servicing on-site or off-site. Contact our team today to schedule heat exchanger cleaning services.

Heat Exchanger Cleaning Services

Heat Exchanger Maintenance Services

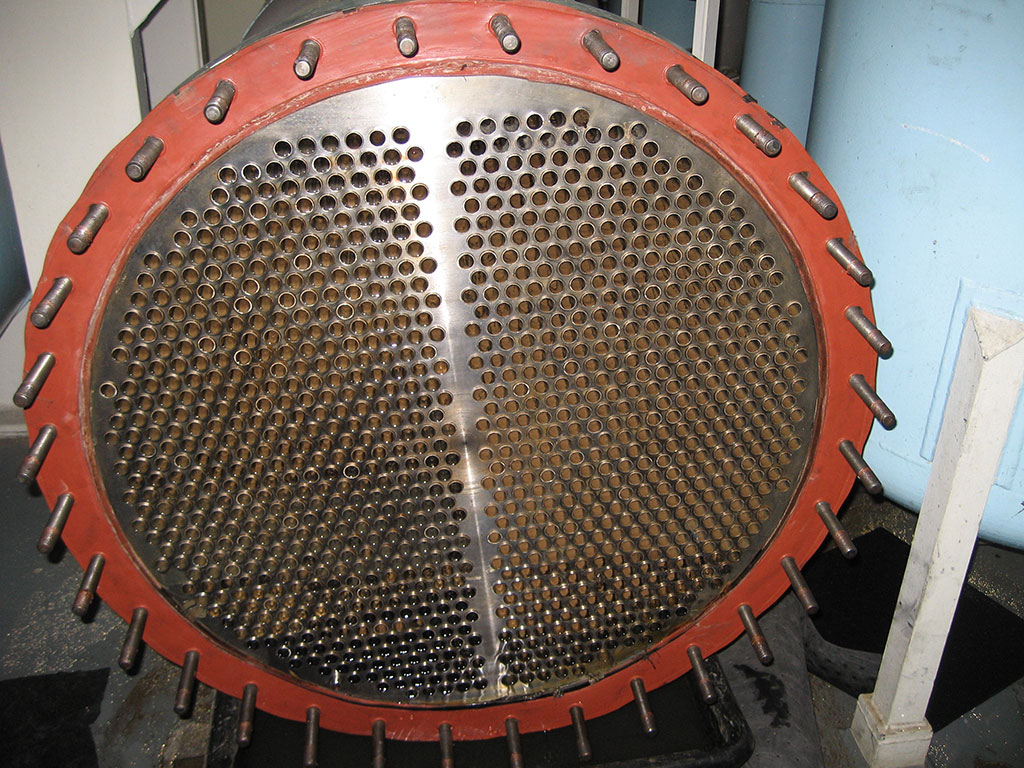

The Merrick Group’s heat exchanger cleaning and maintenance services include:

- Removal of all covers (Rigging Certified)

- Initial inspections and documentation

- Inspections after wipe down

- Coating inspections (AMPP Certified)

- Coating applications (High performance certified)

- Hydrolyzing of pressures up to 40,000 psi

- Plastic brush and metal scraper

- Tube plugging (EST certified)

- Final inspection (FME approved)

- Close unit (Torque certified)

Heat Exchanger Cleaning Solutions

The Merrick Group’s heat exchanger services are the result of years of experience, and training. When you choose The Merrick Group heat exchanger cleaning solutions, our qualified heat exchanger technicians provide:

- Thorough heat exchanger tube cleaning

- Complete heat exchanger coating inspections

- Multiple heat exchanger equipment inspections

- Heat exchanger cover removal and plugging

Our industrial heat exchangers cleaning can accommodate both chemical and mechanical cleaning techniques. We also can accommodate your preference by performing on-site or off-site. For maximum cleaning power, our skilled heat exchanger cleaning specialists employ high-pressure hydro blasting and water lancing.

Trust a professional to clean your heat changer, choose The Merrick Group for quick, efficient, and safe industrial cleaning services. To learn more about our industrial cleaning solutions, call (570) 455-0600.

How Often Should Heat Exchangers Be Cleaned?

The Merrick Group recommends cleaning heat exchangers at regular intervals. Based on the type of service and size of the system, we recommend cleaning your heat exchanger 1-3 times per year.

Regular heat exchanger maintenance will help ensure that the systems are working in an efficient manner, free from debris and other waste. A small amount of dirt can cause the heat exchanger system to work harder, thus causing extra stress on the components.

Regular heat exchanger servicing can identify and fix potential issues before they get worse. Contact The Merrick Group to schedule your heat exchanger inspection.

How Much Does It Cost to Clean a Heat Exchanger?

The cost to clean a heat exchanger will range depending on a number of factors. Like with most machinery, it is often a lot cheaper to regularly clean and inspect your heat exchanger system than to replace it.

Cleaning heat exchangers requires specialized tools, skills, and processes, so it’s best to leave the job up to a professional heat exchanger cleaning company. The Merrick Group can provide a personalized quote based on your specific heat exchanger usage and system size. Call us to discuss your heat exchanger service.

Industrial Heat Exchanger Servicing

The Merrick Group services industrial heat exchanges for a wide range of facility types. These include:

- Nuclear power plants

- Fossil power plants

- Chemical plants

- Petrochemical plants

- Petroleum refineries

Natural gas processing plants

For more information, contact us at 570.455.0600!

McGuire could not have been successful without you. Outstanding job this outage. The engaged leadership, Craftsmanship, and Questioning Attitude stood out to me this outage. McGuire U2 is in a better place now as your work winds down vs. when you arrived (NV Letdown HX, Condensate Coolers, 2A LT HX, LG HX, MSR, and Main Condenser). I would say let’s be proud of what we accomplished in M2R28.”

Heat Exchanger Cleaning Service Near Me

The Merrick Group has offices in Pennsylvania and North Carolina but is capable of traveling to our clients all throughout the United States. We have serviced nuclear power plants and thermal power plants across the US.

Our heat exchanger cleaning services are also worldwide. Our technicians have even traveled internationally; examples include cleaning Navy ships in Spain and performing underwater nuclear reactor work in Taiwan.

Send our staff an email to coordinate heat exchanger cleaning service near you: info@mginc.net