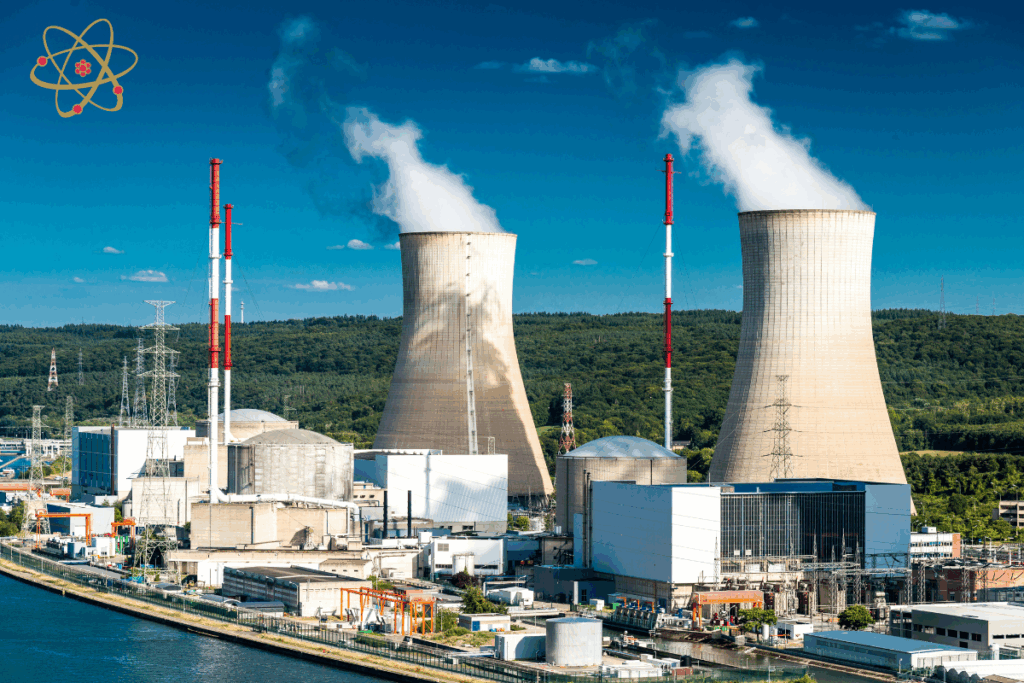

Nuclear facility maintenance is a high-stakes operation with zero margin for error. Safety and strict regulatory compliance are essential in power plants. To prevent serious risks, every task must be handled by highly certified professionals. The environment that is present in a nuclear facility requires only certified vendors to carry out maintenance duties ranging from simple component replacements to complex systematic overhauls.

Nuclear facilities require certified vendors for all maintenance tasks, from basic repairs to complex overhauls. These certifications prove vendors meet the highest industry standards, ensure strict regulatory compliance, and protect both plant personnel and the public.

Talk to a Nuclear Maintenance Expert

The Role of Certification in Nuclear Facility Compliance

Certifications are crucial in meeting nuclear facility compliance. These credentials are aligned to the industry standards created by the Nuclear Regulatory Commission (NRC), the Institute of Nuclear Power Operations (INPO), and each plant’s specific operational requirements. Utilizing these certified maintenance professionals, nuclear facilities can alleviate operational risks and regulatory scrutiny. A partnership with vendors who uphold these high standards and certifications serve as a way to ensure work is completed by professionals who operate under industry standards and readiness for all future audits and inspections. For facilities who are compliant, the process is considerably more effective and efficient when certified nuclear maintenance contractors exercise the expertise, credibility, and reliability.

Key Nuclear Maintenance Certifications to Know

Within the nuclear maintenance industry, there are several key certifications. Understanding the necessity of these certifications are essential to operate and maintain nuclear facilities in the safest and most efficient means. Vendors who hold these stringent certifications demonstrate their commitment to industry’s critical safety and quality requirements.

| Certification | What It Certifies | Application in Nuclear Maintenance | Key Differences |

| AMPP (NACE/SSPC) | Certifies professionals in the inspection and application of protective coatings and corrosion prevention. | Ensures that the protective coatings on pipes, vessels, and other equipment are applied correctly to prevent corrosion. A certified inspector ensures the integrity of these protective barriers. | AMPP focuses on technical expertise in material science and corrosion prevention. AMPP’s aim is to protect the physical assets of the plant from degradation. |

| EPRI (Electric Power Research Institute) | Certifies professionals and procedures in nuclear-specific technologies like nondestructive evaluation (NDE) and welding. | Validates a team’s methods and equipment for inspecting and repairing critical components meet or exceed nuclear industry standards. | EPRI focuses on specialized, nuclear-industry-specific research and development. EPRI addresses highly technical tasks and procedures unique to power plants. |

| OSHA 10 and OSHA 30 | Certifies general workplace safety. OSHA 10 provides a basic overview of workplace hazards for workers and OSHA 30 is for supervisors and the management and enforcement of safety on a job site. | Establishes a foundational understanding of general construction and industrial safety rules. | OSHA focuses on general workplace safety regulations. OSHA keys in on personal safety and hazard recognition for all employees on site. |

Understanding key certifications like AMPP, EPRI, and OSHA is vital in the nuclear maintenance industry. These credentials ensure teams meet the industry’s strict standards for safety, quality, and reliability.

Talk to a Nuclear Maintenance Expert

How Do Certified Nuclear Maintenance Teams Impact Safety and Performance

Certified nuclear maintenance teams increase facility safety and performance by promoting standardized practices that are the core of the industry. Teams that are trained and certified exhibit the rigor of the industry’s safety protocols, hazard recognition, and emergency responses. The integration of this knowledge through certification ensures that all personnel clearly communicate and operate within the exact procedures required. The result is certified contractors reduce potential risks and improve operational reliability. Data proves that nuclear facilities employing this proactive approach have a much greater outage efficiency and consistent plant uptime.

Why Do Nuclear Maintenance Certifications Matter

When it comes to selecting a trustworthy nuclear maintenance company, certifications are important indicators that they are committed to maintaining credibility. Vendors who have worked diligently to obtain these credentials demonstrate their investment in formal training, adherence to industry standards, and a record of successful project completions. Certifications enable clients to objectively evaluate vendors by means of their verifiable qualifications. Certified teams provide a sense of confidence and minimize risks with a greater likelihood to meet deadlines, operate with a budget, and competently meet expectations.

Why Merrick Prioritizes Nuclear Maintenance Certification

At the Merrick Group, we prioritize training our teams to become certified AMPP inspectors. Our core is founded on safety, quality, and excellence in nuclear facility maintenance. We are invested in excellence and position ourselves at the front of the industry with great emphasis on recertification, ongoing training, and upholding the most rigorous internal quality standards. Our personnel hold key certifications of AMPP and ANSI N45.2.6-1978. Our proactive approach facilitates industry-leading nuclear safety practices by applying the latest knowledge and procedures to your facility’s maintenance.

Choosing the Right Nuclear Maintenance Team

Certifications are a necessity in the nuclear maintenance industry. At the Merrick Group, these certifications go far beyond a checklist of complete tasks, but an ongoing process of acquiring the knowledge and skills to perform our services towards the industry standard. We extend our proactive approach to all of our current and potential clients to thoroughly examine the credentials of their vendors. Our steadfast commitment is to excellence and providing over 20 years of industry-leading nuclear maintenance solutions.