Since heat exchangers are integral to critical plant systems in the power generation, HVAC, oil and gas, and chemical industries, overall system performance depends on their heat transfer efficiency. When heat exchanger efficiency declines and inspections reveal multiple leaking or defective tubes, full component replacement may seem like the only option. Before committing to the high cost of a new component and prolonged plant downtime, contact The Merrick Group. Our team of expert technicians can extend the life of your equipment, and improve overall system performance, with heat exchanger retubing services.

Need Heat Exchanger Replacement or Retubing Services?

Understanding Heat Exchanger Maintenance

Heat exchanger services are essential for maintaining optimal temperatures, improving energy efficiency, and ensuring safe operation in various industrial processes. Offering an environmentally friendly way to reduce costs, heat exchangers recover and reuse heat from exhaust gases, usually by condensing steam or gases back to its liquid form. Over time, a heat exchanger can fall victim to fouling due to corrosion, scaling, leaks or general wear and tear from the repetitive expanding and contracting due to the changes in temperature.

When Should You Do Heat Exchanger Retubing?

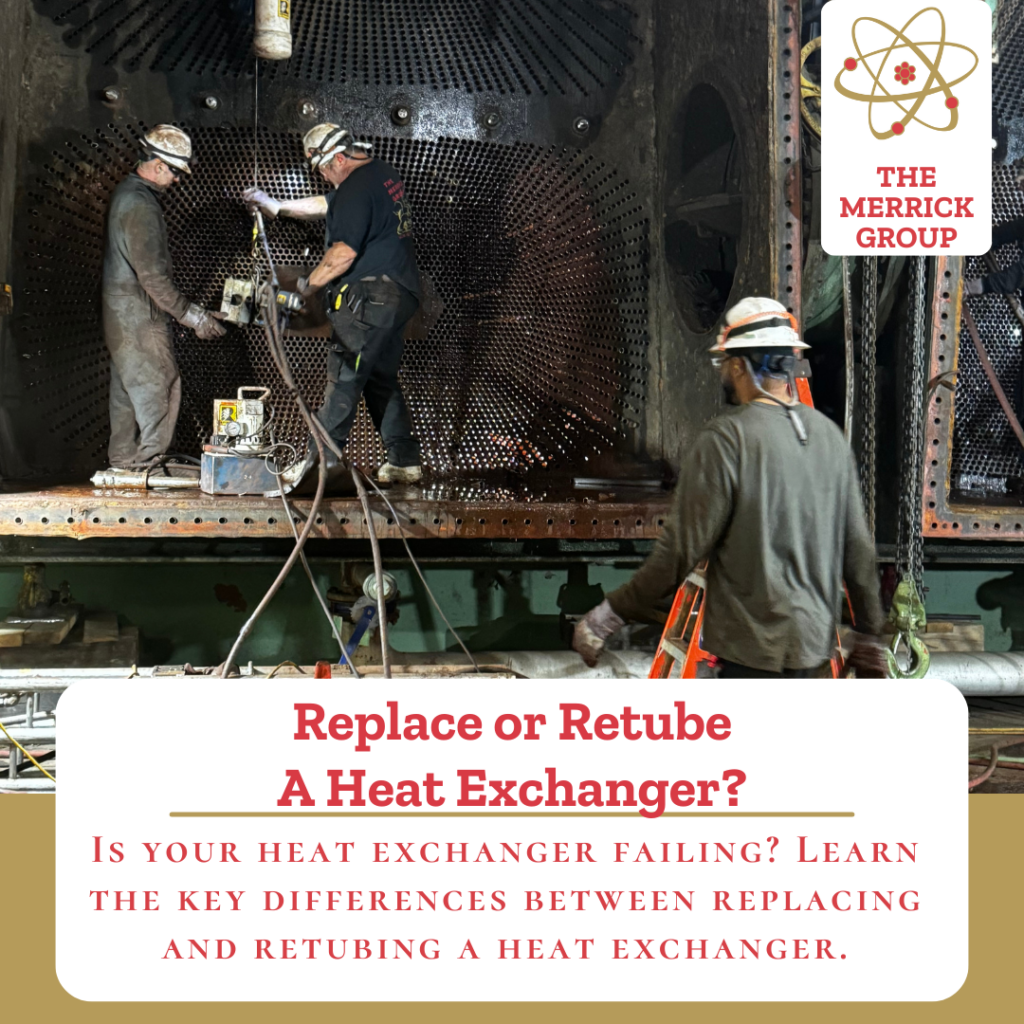

The retubing of a heat exchanger is the process of removing the old tubes and replacing them with a new tube. When you opt to retube your heat exchanger, an experienced industrial retubing company like The Merrick Group will remove the tube-to-tube sheet welding (if needed), then remove the tube. After cleaning the area, the new tube will be inserted. The area will be re-weld (as needed) and a hydrotest will be run.

The retubing process is a much more cost-effective solution than replacing an entire heat exchanger, bringing the system’s production back online quickly.

When Should You Replace a Heat Exchanger?

An industrial heat exchanger replacement is needed when it is suffering from mechanical failure, structural damage or if the system can no longer run on its outdated technology. A full heat exchanger replacement means complete removal of the old unit.

The process includes dismantling the old system, installing a new exchanger, and ensuring proper integration with existing piping, insulation, and controls. Replacement may be necessary when repairs are no longer cost-effective, performance has significantly declined, or the system no longer meets operational requirements.

Proper planning and installation are crucial to minimizing downtime and ensuring long-term efficiency. Get a free consultation on whether replacement of your heat exchanger is necessary by contacting the experts of The Merrick Group.

Get Heat Exchanger Maintenance

Key Factors to Consider When Choosing Between Retubing and Replacement

- Cost Analysis

Retubing a heat exchanger is significantly cheaper than full replacement, making it a practical option if the shell, headers, and other components are in good condition

- Downtime Impact

Retubing can often be completed faster than a full replacement, reducing operational disruptions and keeping production running efficiently

- Lifespan & Performance

If this is the first or second instance of tube failure and the exchanger has otherwise performed well, retubing provides a nearly comparable long-term efficiency option to a full heat exchanger replacement

- Environmental Considerations

A well-executed retubing can restore the heat exchanger to near-original efficiency levels and significantly reducing greenhouse gas emissions without the added costs and complexities of full replacement

Advantages of Retubing vs. Replacing a Heat Exchanger

Heat Exchanger Retubing AdvantagesRetubing a heat exchanger offers significant advantages over a full replacement, particularly in terms of cost, downtime, and system longevity. It is a more cost-effective solution, as replacing only the tubes is far less expensive than purchasing and installing an entirely new unit. Additionally, retubing minimizes operational downtime since it can often be completed on-site and requires less extensive labor compared to a full system overhaul. By restoring the exchanger’s efficiency and functionality, retubing extends the lifespan of the existing unit, allowing businesses to maximize their investment while maintaining optimal performance. |

Heat Exchanger Replacement AdvantagesA full heat exchanger replacement provides the advantage of upgrading to a new, optimized system that incorporates modern technology for improved efficiency, reliability, and performance. Newer designs offer enhanced heat transfer capabilities, better materials resistant to corrosion and fouling, and compliance with updated industry standards. Replacing the entire unit eliminates any previous structural weaknesses, preventing recurring maintenance issues and costly repairs. Additionally, modern heat exchangers are often more energy-efficient, reducing long-term operational costs while ensuring seamless integration into evolving industrial processes. |

Schedule Heat Exchanger Services

How to Determine the Right Solution for Your Heat Exchanger

A reputable company can usually come out to inspect the performance of your heat exchanger and help you determine the right course of action. They can also assist with scheduling routine inspections to ensure problems are identified before they become a bigger problem that may require a full replacement.

The Merrick Group has some of the best heat exchanger technicians that can service industries across the world. Our experienced heat exchanger inspectors are trained to identify corrosion, damage, failure and fouling. We also have certified Eddy Current Testing inspectors (ECT inspectors) to assess heat transfer efficiency, pressure levels, and structural integrity to identify potential failures before they cause operational disruptions. Techniques like visual inspection, ultrasonic testing, and thermal imaging help detect hidden defects.

Trust experienced The Merrick Group technicians with the productiveness of your heat exchanger system.

Making the Best Choice for Your Equipment

With decades of experience, The Merrick Group can offer an extensive list of pros and cons about replacing or retubing your heat exchanger. Providing you comparative details about the costs, downtime, the longevity of the system, technology and industry compliance/standards between the retubing and replacement.

With extensive experience in both heat exchanger retubing and replacement processes, we are excellently situated to help you make the best decision for your industrial systems.