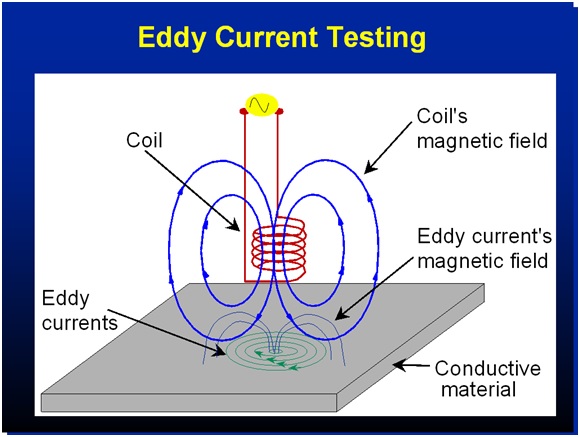

Eddy current testing is a non-destructive test (NDT) method that can be performed on conductive materials. A test coil that is energized with alternating current is placed close to the test surface. This generates an alternating magnetic field that produces eddy currents in the test piece. Variations in eddy current flow produce a measurable change in the test coil. These changes are shown on a screen and interpreted to identify defects. The presence or absence of flaws in the test specimen can be determined by monitoring changes in the impedance of the eddy current test coil. Changes in coil impedance are displayed as voltage changes in terms of signal amplitude and signal phase. These variations in phase angle and/or signal amplitude are correlated to flaw conditions, such as percent wall loss and volumetric wall loss.

The eddy current inspection method can be used to detect degradation as well as determine the test part’s conductivity, and the thickness of coatings applied to conductive materials.

How Do Eddy Currents Work?

Eddy currents are formed by an alternating magnetic field as an energized A/C coil nears a conductive material.

When there is a defect in the material, the flow of the currents changes and can be detected by measuring the impedance changes that occur in the A/C coil. This method of testing is a very efficient non-destructive method for finding defects in the heat exchanger and condenser tubing.

What Is Eddy Current Tube Inspection?

A common application for eddy current testing is tubing inspection in heat exchangers and condensers.

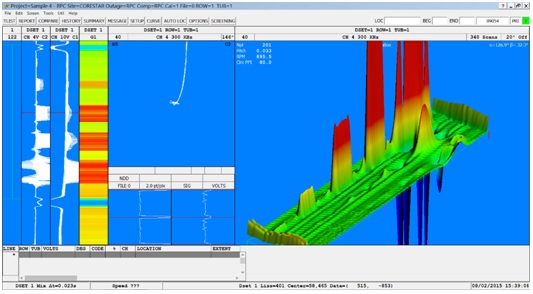

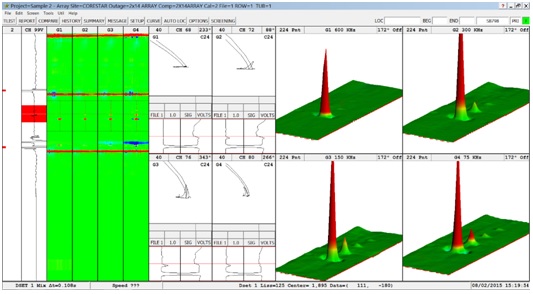

Eddy current testing uses electromagnetic induction to identify defects in the tubing. A probe is inserted into the tube and traverses the entire length of the tube. Eddy currents are generated by the electromagnetic coils in the probe and monitored simultaneously by measuring probe electrical impedance.

Eddy current non-destructive testing involves inspecting eddy current tubes to discovering defects. It is effective on a number of different tubing materials, and can detect defects that can create larger issues for the heat exchangers and condensers.

Schedule Advanced Eddy Current Inspection

What Are Some Types of Non-Destructive Testing?

Other NDT techniques include visual testing, liquid penetrant examination, ultrasonic testing, magnetic flux leakage, and magnetic particle testing.

Several types of defects can be detected in tubing with the eddy current test method:

- Inner-diameter (ID) and Outer-diameter (OD) pitting

- Cracking

- Wear (from support structures, other tubes, and loose parts)

- OD and ID Erosion

Contact Us For Eddy Current Testing Services

What Kinds of Materials Can Be Tested With Eddy Current Testing?

Eddy current testing can successfully test any conductive, non-magnetic, or mildly ferromagnetic materials. This would include materials such as nickel alloys and ferritic chromium-molybdenum stainless steel.

What Kind of Inspections Can Be Performed Using Eddy Currents?

Eddy current inspection techniques include, but are not limited to:

- Eddy current test of heat exchanger tubing

- Inspecting the integrity of welds and bolts

- Checking heat-treated materials by testing conductivity

- Inspecting metal surfaces for defects

- Determining whether the metal has corroded

This is very useful for testing the integrity of structures made of conductive materials like copper, steel, and aluminum because the results are immediate and you do not need to touch the actual metal. If you need to verify that a conductive material like a pipe is not cracked, pitted, or corroded, these testing techniques will get the job done. You can use them to determine the thickness of a non-conductive coating, such as paint, is and determine metal hardness. Verifying that heat exchanger tubing is not degraded is an example where eddy current testing is often used.

Call to Schedule Eddy Current Tube Inspection

What Types of Probes are used During Tubing and Surface Inspection?

Many probe types, from simple single-coil probes to array probes with over 50 coils can be used for tubing and surface inspections. The expected damage mechanisms and the geometry of the test specimen determine the coil configurations that are used.

Ready to Schedule Your Eddy Current Inspection?

The Merrick Group is a knowledgeable and reliable eddy current inspection company that is able to assist customers anywhere in the world. With over two decades of experience assisting our clients with their eddy current testing, we are the reliable experts in the industry.

Whether it is your initial or next eddy current inspection, contact us today for scheduling!